MultiTester

MultiTester

MultiTesterApp ver 1.0

Application is designed to work with various measuring devices equipped with DIGIMATIC USB interface. It allows to register and evaluate values of measurements according defined value of tolerance then store and send results of measurement session by e-mail.

For correct verification of measurements is required proper settings of the maximum and minimum values. The upper limit must be greater than the lower limit. Otherwise, the verification option will be disabled (see menu Settings).

Necessary to proper use (see picture below):

- smartphone or tablet with OTG functionality and operating system ANDROID ver 4.0.4. or later (item 1)

- OTG cable (item 2)

- electronic measuring device (caliper or other) equiped with iterface usb DIGIMATIC (item 3)

- usb DIGIMATIC iterface cable (item 4)

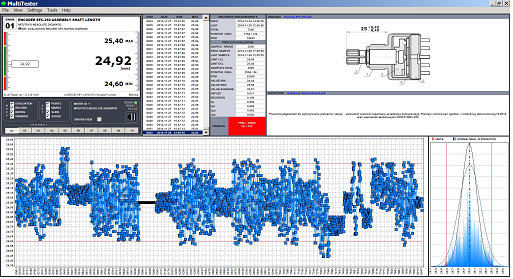

Example of Multitester application

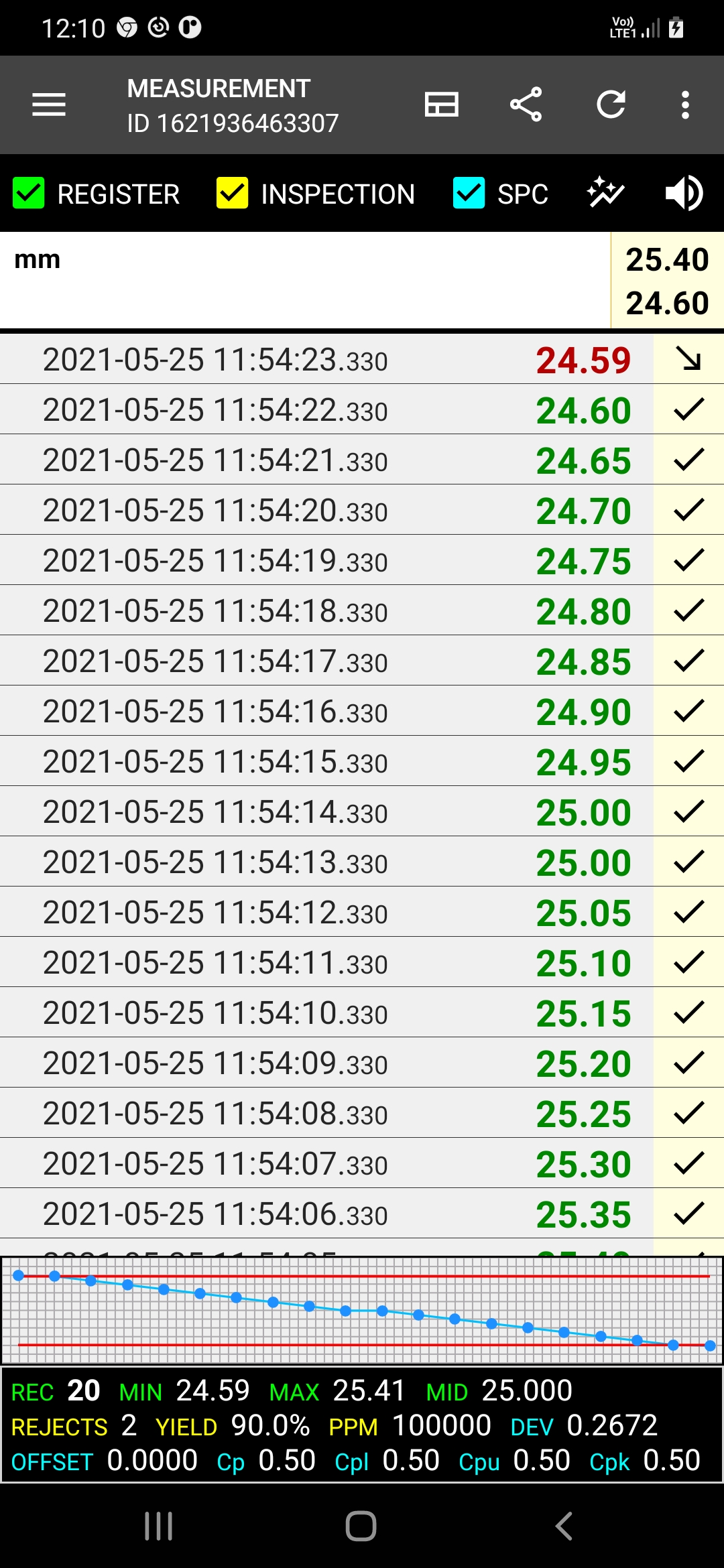

Smatphone screenshot

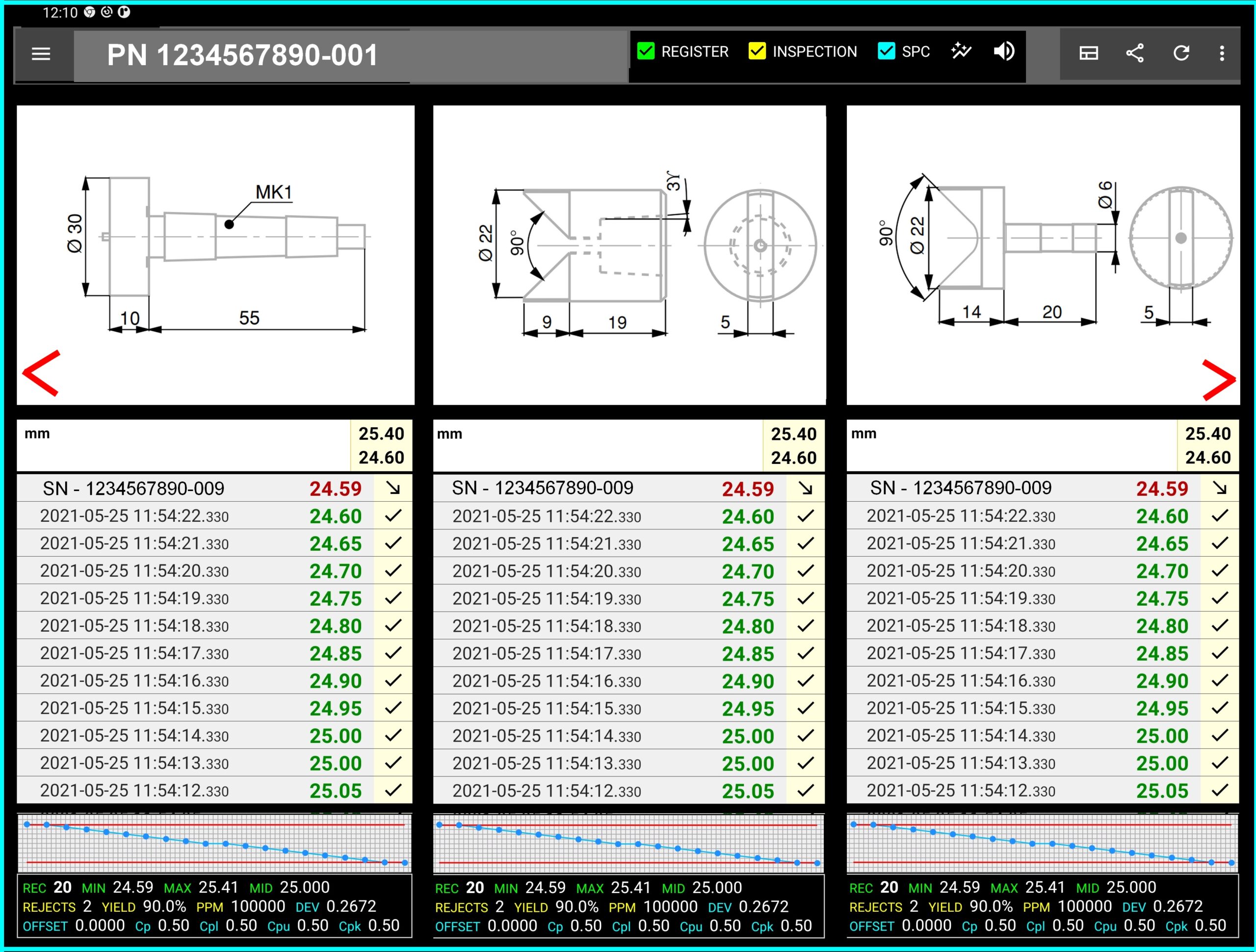

Tablet screenshot – multichannel measurements

Each channel can be connected to a different measuring device, which allows you to measure different physical quantities simultaneously.

Note:

Before attempting to the tests please make sure, that all used measuring devices have a valid legalization certificates. Good practice require a periodic validation of the system with using a pre-prepared test samples. Before start registering measurements please verify that the system date and time correspond to real.

MultiTester ver.2.0

1. Description

MultiTester combine functionality of measurement-registering software and real-time calculating parameters of statistical process control (SPC). In version 2.0 system can work simultaneously with several measuring devices and various physical values.

MultiTester allows to preset up to 10 independent channels.

Each channel can be used for measure different value and with use different device.

All the measuring channels have the following functions:

• graphic and acoustic results presentation,

• value evaluation in accordance with required limits,

• registering date, time and results of measurements

• online calculation of the current parameters for statistical process control: standard deviation, Cp, Cpu, Cpl, Cpk, PPM,

• graphical presentation of the results real and normal distribution,

• warning about exceeding the preset values of SPC parameters

• presentation of shortened and/or detailed related technical documentation,

• presentation of shortened and/or full test stand instructions,

• printouts of quality reports and production data logs

2. User Interface

All relevant information and control buttons are located on the one desktop control panel in a strictly defined area. The information is presented in an intuitive graphical format and updated immediate on a regular basis. Such solution allow to minimize operator efforts important especially in the production environment.

3. Purpose

The program is designed to work with manual, semiautomatic and automatic measuring stands in the laboratories or quality control area of the production plants.

The system can be also directly integrated with automatic production lines working as:

• quality control system to product selection processes,

• production log and quality data reports generator,

• early-warning system allowing to adjust production process before the product parameters exceed required tolerance.

4. Benefits of use

• MultiTester allow to build multifunctional measuring stands provided to measuring and verification of several product parameters. Moreover the measured parameters can be different physical values (length, weight, response time, temperature, resistance, humidity, etc.). It depends only on device used. Reducing the number of stands allow to reduce amount of necessary equipment, occupied space and staff provided to support.

• The program in real-time determines parameters of the statistical process control Cp and Cpk. After each stroke they are updated and immediately available for process evaluation purposes. This is especially important for the quality control process in automated and high-volume production environment.

• A graphical representation of the recorded measurements enables intuitive tracking and analyzing process trends in relation to the nominal and boundary values. It allows to react and adjust production process in advance, before the limits are exceeded. That has a direct impact to reduce costs associated with amount of defected parts.

5. Compatibility

The standard version of the program is working with Mitutoyo digital devices equipped with Digimatic communication interface.

To establish communication with the other measures is necessary to install a software driver designed for particular device.

6. Requirements

• Standard PC computer,

• MS Windows XP, Windows 7, Windows 10 (32/64 BIT),

• Recommended screen resolution of 1366×768.